Letterpress printing depends on a raised image, it’s known as a relief process. Movable type was the breakthrough that allowed printers to use and re-use individual characters. When you practice letterpress printing it’s easy to forget just how difficult it must be for type founders to create tiny pieces of cast metal hard enough to withstand a tremendous force that are made to tolerances of less than one thousandth of an inch.

Gutenberg of Germany is credited with the invention of moveable type around 1450; but records show that both Chinese and Korean inventors had used the idea before the time. Gutenberg’s invention was the first to be exploited and the idea spread rapidly. There are three key stages in founding type –

- Punchcutting: creating a three-dimensional representation of the letter in the end of a bar of metal. This skilled work requires a number of other punches and tools to be used to create the punch, and then it be subject to hardening. Modern-day equivalents of punches can be seen in DIY stores to mark metal equipment with initials.

- Creating the Matrix: this step takes the punch, and strikes it in a softer metal to make a negative mould. The metal is usually brass

- Casting: this is filling the mould with molten type metal and removing the cast type

Type Founding in the Printing Economy in the UK

Type founding is a specialist industry needing artistic and design skills in equal measure with engineering prowess and ability to work in some of the very heavy aspects of industry. The industry was centred around the demand in Fleet Street, London; but other significant type founders worked where technical expertise was greatest-for example Stephenson, Blake of Sheffield.

The key constraint for printers was that type from a foundry had to be assembled by hand before printing could begin. This composition activity took a great deal of time and tied up capital in the type needed. As the 19th century grew to a close people we very keen to automate this part of the process-work began to look at producing type in the order it was needed. That’s to say go directly from the copy to the metal type with no sorting or composing process in between.

There became two families of type: foundry type (generally harder quality) that was produced in the great foundries; and composition type (slightly softer quality) that was produced from copy either by a specialist firm, or even by the printer himself.

UK Type Foundries

The UK had a number of very influential foundries. While early metal type from the continent (in particular Dutch type) was considered superior, the UK caught up and great names like Caslon, Figgins and Stephenson, Blake were established. The large number of small foundries gave way to a smaller number of large foundries. The last of the English Foundries, Stephenson, Blake of Sheffield stopped trading in December 2004. That foundry alone had acquired Charles Reed and Sons in 1905, and H. W. Caslon and Co in 1937.

Composition Type

Allowing printers to cast their own type was a key driver behind developments in composition type. There were two broad approaches: build a complete line of type from a machine; or build individual characters in the correct order from the machine.

Linotype and Intertype took a similar approach: the operator sat at a keyboard and typed the copy. While copy was being typed the matrices (type moulds) were assembled within the machine. Once a line was completed the moulds were filled with hot type metal and the resulting ‘slug’ was forced from the machine, being trimmed and shaped in the process. The Ludlow Typograph was similar, but the matrices were assembled by hand.

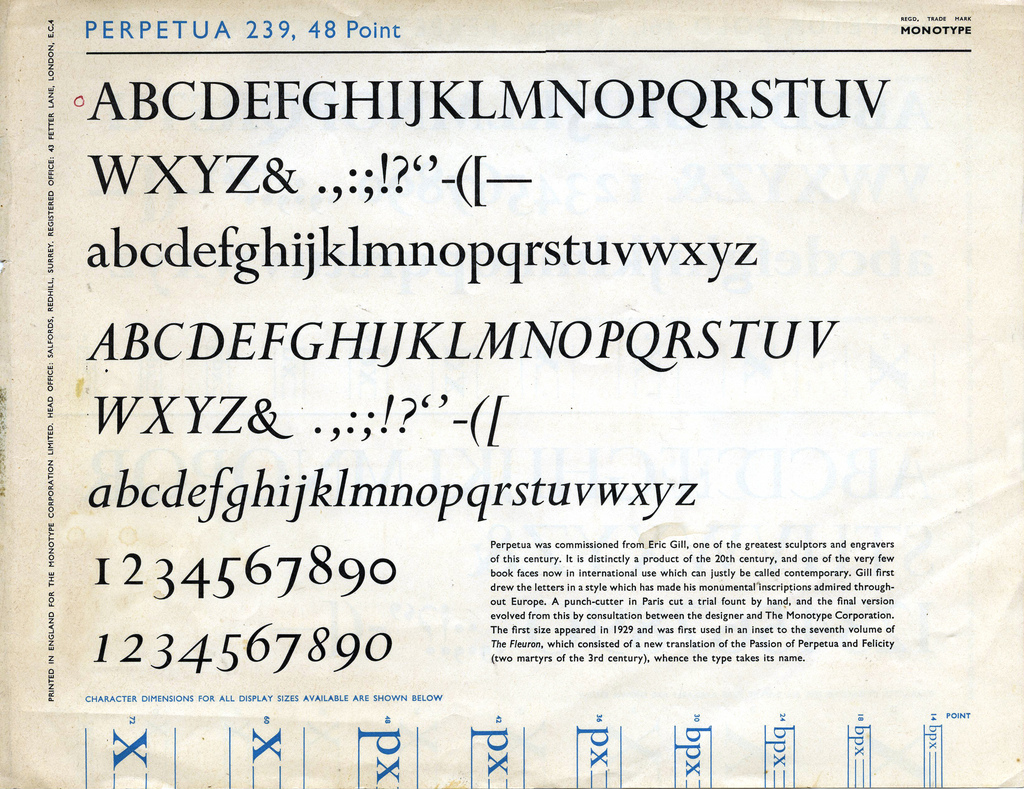

Monotype adopted a different tack. They split the operation between keying the copy and casting the type. Copy was typed on a Monotype Keyboard powered by compressed air which punched holes in a paper tape. The tape was then taken to a casting machine which used the paper tape to position a case of matrices and cast a single piece of type for each keystroke on the paper tape. The advantage of this approach was to allow for correction after composition had been produced by the machine.

In modern times, Monotype machines can be controlled by computer–allowing the direct production of metal type from a computer keyboard.

In This Section

Choosing Typefaces

A starting point for the age-old problem of choosing a house face

The Point System

How did we in the English-speaking world arrive at 0.01387” as one point?

Type Synopses

The obscure join between maths and printing — making sure each letter is in the right proportions

Type Founders

Other UK type founders

Linotype and Intertype Salvage

A guide — in note form — to salvaging a Intertype or Linotype

The Monotype System

The system that spawned a great name in letterpress and the typography we use today

The Ludlow Typograph

The less-popular brother of the Intertype/Linotype and the Monotype system

Elrod Strip and Rule Caster

The machine used by smaller printers to cast new ‘strip material’

Woodletter or Poster Types

Bigger type to produce those wonderful inky letterpress posters

Finding Second-Hand Type

How to find and buy second-hand type

Further Information

- Dave Huges’ MetalType.co.uk site focusses on non-foundry type, especially Intertype and Linotype machines. The site also includes some letterpress-related classified adverts