Article by Tony King

I bought a Haddon Gordon 15 x 10 in 1985 after years of treadling a C & P, and was curious to know the lineage of this particular brand. I was familiar with Arabs, Croppers, and other Gordons but not the name of Haddon.

My research found that Haddon was the leading advocate for the adoption of the American point system in England which saw its progressive introduction at the turn of the 19th century. Not only an advocate but the entrepreneurial flair of Walter Haddon saw him overwhelm the market — and naturally cause an uproar in the casting industry.

My early research traced my presses’ life in New Zealand to the New Zealand representative for John Haddon & Co of Market Harborough, England. This was A. D. Willis a printer and importer in Wanganui highly respected in Australasia in the 1880’s for his exquisite lithographed scenic postcards of New Zealand. Shortly after buying the press I visited Wanganui to buy cases of redundant type from a newspaper’s loft, and discovered with some amazement that the building carried the foundation stone for A. D. Willis, Printer.

In 1989 I visited the St Brides Library in London and started my research in earnest, later to be supplemented by a great deal of information from a 1914 issue of the British Printer in which they were marking the centenary of the establishment of the Haddon business in 1814.

The recorded Haddon dynasty which was based in Naseby Northamptonshire goes back beyond 1700, and the lineage fathered several John Haddons and the one that eventually started the printing empire was one of 11 children and born in 1823.(1823–1904) The family were farmers but John born in 1784 (1784−1855) did not have farming inclinations “but was noted for his literary tastes although it was as a businessman that he made his mark. He was apprenticed to a printer at the age of 15 (1801) and after a year went to London to seek his fortune.” In 1814 he founded the printing business which celebrated its centenary in 1914. His early printing included much for Baptist missionaries especially literature for foreign missions in which his father was also particularly interested. They saw the potential of spreading their business ambitions beyond printing and the British Isles and often had requests from missionaries to be sent items in addition to their books and pamphlets. As a result they established a ‘general commission agency’ which gave them the opportunity to be in touch with all parts of the world.

The third John born in 1823 was also apprenticed as a printer and superseded his older brother to become the sole proprietor in 1855. However his passion for printing was overshadowed by his interest in philanthropy, religion, music and gardening and the business suffered as a result. He bowed out of an active interest in the company when in 1888 cousin Walter Haddon joined the firm as a partner and became the sole proprietor in 1890. At that time there were three employees, by 1898 one hundred.

Walter possessed the qualities to turn the fortunes of the company around and his entrepreneurial skill had him expanding the business, acquiring well established engineering companies that would compliment his future direction. He established an advertising agency, and developed the skills of direct marketing and mail order

In 1898 in an interview with The British & Colonial Printer & Stationer he spoke of the frustration of many printers in not having a universal type casting standard in England and he’d observed from his contacts in America and from type that had been imported, the advantage of the standard developed in America. The American system was the work of Nelson Hawks a printer in San Francisco when in 1871 he proposed the establishment of uniform body sizes, but it was not until 1886 that the American System of Interchangeable Type Bodies was accepted. Caslon were first of the mark in 1886 announcing a scheme for the new body measurement and it was officially adopted in England in 1889. Haddon came on the scene in 1897 with a vengeance:

“For more than half a century this reform has been discussed, but persistently and stubbornly resisted, if not ignored by typefounders. Repeatedly have printers complained of the inconvenience, the annoyance, the expense, to which they have been needlessly put by the policy of the founders in the matter of each having different standards. No notice has been taken of their complaints, their reasonableness and gravity could not be denied, but no remedy was offered until type from America and other foreign foundries found its way into this country and was eagerly purchased by printers.”

Behind the resistance was the cost of converting to the new system and Haddon had his enemies. An Associated Type Founders lobby group appeared attempting to undermine the momentum for the new point system. Known as “the Ring” by Haddon supporters, Walter chose to use his Type Catalogue of 1902 to challenge them throughout his type sample pages. In Haddon Old Style he says “The ‘Ring’ Founders cast type to indefinite widths, and so justification of the larger types is again a matter of oddments of lead, pieces of card or paper, spiked quads and much waste of time and material.”

In 1898 Walter established his massive Caxton Type Foundry at Market Harborough in Leicestershire, and trumpeted the virtues of the system to the industry. His foundry covered two and a half acres and included not only type casting but the production of a full range of printers’ tools, accessories, wood type and cabinets and by now his workforce had reached 1500.

His brash advertising and aggressive marketing was commented upon in The British Printer: “Although the methods of promotion adopted at the time were, to put it gently, somewhat of a shock to the established trade, and truly were far from commending themselves to many members of the printing industry it will be accepted that the Haddon foundry had the courage of its convictions and certainly did not mince matters either in argument, advertising, in claims and in replies to opponents.” Walter travelled throughout Britain and to the Continent extolling the virtues of the new point system and the superiority of the type from his new foundry – and found willing converts wherever he went. According to H.W. Larkin in ‘Compositors Work in Printing’ some printers were still using the old body type as late as 1935. And while giving priority to the prosperity of the Caxton Foundry, the company continued to develop the Export and Buying Department that had been the beginnings of international trade back in the earliest days of ‘missionary trading.’ Trade was extensive in both directions acting as a buying agency in England and Europe for the “Indian and Colonial centres everywhere in exporting motor cars and motor cycles, clothing, hardware, provisions, and ammunition” while sourcing buyers in England for products from “planters and storekeepers in Asia, the West Indies, the South Sea Islands, Australia, New Zealand Central and South America and Congo Belge”. In 1894 they struck a boom in the export of rubber plants, nurtured from seedlings in England, to Ceylon and the Malay States, and were the first to introduce and import crepe rubber into England. They also imported elephants and rhinoceros to order from Africa.

The manufacture of zinc and copper plates for ‘process’ purposes had up until about 1914 been confined to American and German sources. Haddon acquired a copper and zinc plate factory in Clapham and became the only works of its kind in the British Empire, and produced a very high standard of plate. Demand from English printers and engravers was overwhelming and further enhanced the reputation of the Haddon brand.

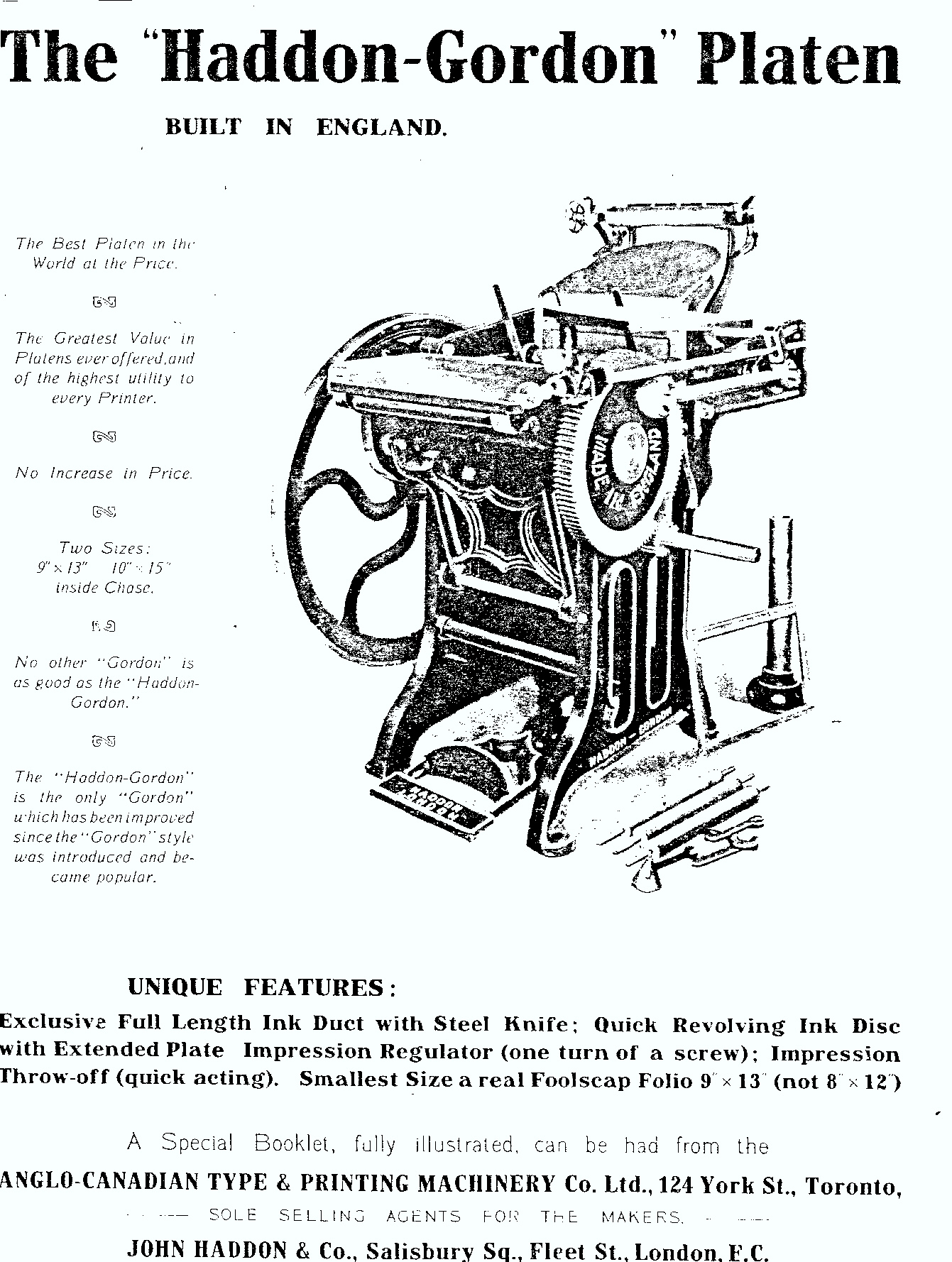

The Haddon-Caxton Types, Borders, and Rules catalogue on 1902 lists the presses available at that time as the Haddon High Speed Safety Platen, the Babcock Standard Drum Cylinder press, The Babcock Optimus, The Art Caxton Platens and Swift Platens.

The treadle and later motorised Gordon platens appear to have been manufactured from about 1861, the Minerva built by H S Cropper appearing in 1867 and by 1894 no less than eleven firms were manufacturing Gordon presses. This would suggest my favourite 15 x 10 Haddon Gordon could be about 115 years old.

References: The British Printer (an issue of 1914)

British & Colonial Printer & Stationer March 24 1898

Haddon the Head Hunter – A.Hingston-Quiggin 1914

History of the Haddon’s of Naseby – W. G. Croft 1915

Compositors Work in Printing – H. W Larkin 1961

Haddon-Caxton Types and Borders Catalogue 1902

The Dorman Association has documented more information about the manufacturer of the Haddon Press.

This article and photos courtesy of: Anthony R. King

Tony King started letterpress printing as a schoolboy on an Adana HS2 in 1953 printing just two issues of a four page “Third Forms Mini Mag” before resorting to adding pages duplicated from an “Emgee Memo Stamp” duplicator. Years later – career and family intervened – he imported an Adana HQ and subsequently moved to a C & P 15 x 10, Pearl treadle, Kelsey 9 x 6, Adana 5 x 3, and Haddon Gordon. Today at his home in Greytown, north of Wellington N.Z. he operates an Adana HQ, Adana 8 x 5, Adana HS2, a 1910 Sigwalt No 11, and Farley Proof press, and at the Greytown Early Settlers Museum opened a print shop in July 2010 based around a Challenge Gordon 15 x 10 (1894) and T.C. Thompson (Manchester) Gem No 3 (1926); Penrose Proof press, and two Adana HS No 2. Tony is a foundation member of the Association of Handcraft Printers (New Zealand), and moderator of the Yahoo Group ‘letterpressdu’ (letterpress down under).